Overview

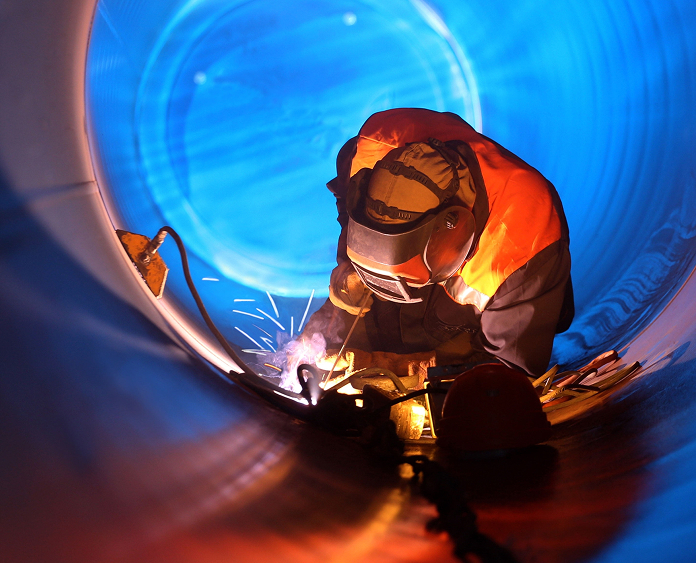

The metal and steel industry lies at the foundation of global infrastructure — from buildings and bridges to automobiles and machinery. But as production scales and competition intensifies, the industry faces growing pressure to balance efficiency, cost and quality.

CorporateServe Tech understands these complexities. Our industry-specific ERP solution, MetalSoft, built on SAP S/4HANA, helps metal manufacturers digitise, automate and optimise their operations, ensuring superior control, precision and profitability.

Key Challenges in the Metal Industry

- Volatile raw material prices and dependency on LME rates.

- Inefficient tool and die planning leading to production delays.

- Managing weight, volume, and multiple alloy combinations.

- Complex supply chain and inventory traceability.

- Lack of real-time visibility across procurement and production.

- Manual scrap management and reconciliation issues.

- Pressure to meet tight delivery timelines and quality standards.

Why ERP for the Metal Industry?

Core ERP Modules for Metal Manufacturing

Key Functional Modules in MetalSoft Include:

AI That Powers Precision in Metal Manufacturing

CorporateServe integrates AI and predictive analytics within MetalSoft to empower manufacturers with real-time insights, automation and foresight.

Predictive maintenance

Predictive maintenance for heavy machinery and furnaces.

Automated LME

Automated LME rate adjustment and forecasting.

Quality Anomaly Detection

Quality anomaly detection through production data analysis.

AI-driven scrap and yield optimisation.

AI-driven scrap and yield optimisation.

Smart Dashboards

Smart dashboards for cost tracking, consumption analysis and performance benchmarking.

With AI at the core, MetalSoft enables metal manufacturers to minimise waste, reduce downtime and maximise profitability.

Key Benefits

- Centralised visibility across sales, production and finance.

- Reduced manual errors through automated reconciliation.

- Optimised production planning and real-time cost tracking.

- Seamless integration of LME rates and financial forecasting.

- Improved supplier collaboration and procurement accuracy.

- Quick, data-backed decision-making with real-time analytics.

- Enhanced profitability through scrap reduction and inventory control.

- Industry-ready deployment with just 4 months of implementation.

Integration Capabilities

MetalSoft, powered by SAP S/4HANA, integrates effortlessly with existing enterprise systems and external platforms to deliver unified control and continuous data flow.

How ERP Supports Industry Standards?

MetalSoft aligns with the global best practices and quality frameworks of the metal and steel industry:

ISO 9001 / ISO 14001

Quality and environmental management.

IATF 16949

Automotive and metal component manufacturing compliance.

Occupational Health & Safety (OHSAS) integration.

Environmental and sustainability reporting.

Advanced audit trails for material and process traceability.

Why Choose Us?

Our Strengths:

A legacy of successful ERP implementations across sectors, backed by unmatched technical depth and delivery excellence.

Authorised partners of SAP, Microsoft and Epicor, giving clients access to world-class platforms and continuous innovation.

From consulting and implementation to managed services and optimisation, we take full ownership of your digital journey.

Every solution we build is driven by our clients’ goals, ensuring measurable business value and sustained success.

We integrate AI, analytics and automation into every solution, turning technology into a competitive advantage for the modern enterprise.