Overview

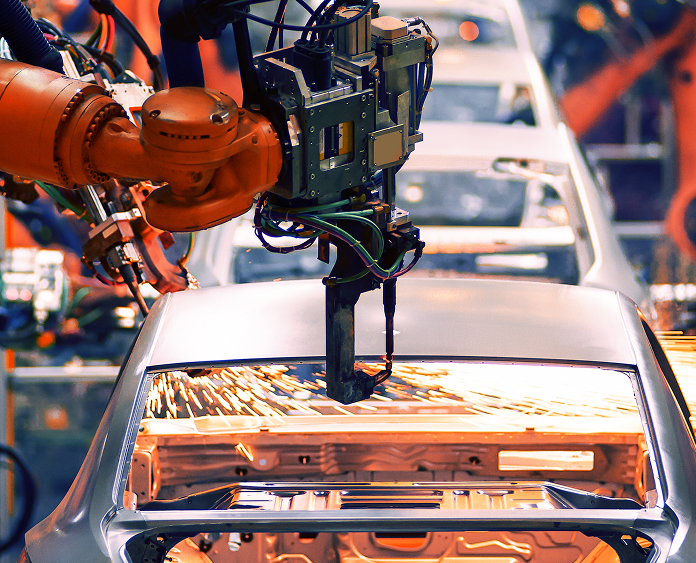

The manufacturing industry is built on precision, efficiency and adaptability. Whether it’s automotive components, electronics or industrial machinery, manufacturers today face constant pressure to deliver faster, reduce costs and maintain product quality.

CorporateServe Tech empowers manufacturing enterprises with SAP S/4HANA-powered ERP solutions that connect every function, from design to delivery, into one intelligent digital ecosystem. Our solutions streamline planning, production, procurement and performance tracking to help you achieve operational excellence and sustainable growth.

Key Challenges in Manufacturing

- Managing complex Bills of Materials (BOMs) and version control.

- Synchronising production schedules with fluctuating demand.

- Balancing capacity utilization across multiple plants.

- Handling frequent engineering changes and product updates.

- Maintaining real-time visibility across supply chains.

- Managing high-cost inventory and material wastage.

- Ensuring timely delivery without compromising on quality.

Why ERP for Manufacturing?

Core ERP Modules for Manufacturing

CorporateServe’s ERP system for Manufacturing includes:

AI That Makes Manufacturing Predictive, Not Reactive

CorporateServe Tech integrates AI-driven intelligence into manufacturing to empower data-backed decisions and operational agility.

Predictive Demand Forecasting

Anticipate market shifts and plan capacity accordingly.

Production Optimisation

AI-based recommendations for efficient resource utilization.

Smart Maintenance

Predict and prevent equipment downtime with sensor data.

Quality Insights

Detect anomalies early with AI-based defect tracking.

Intelligent Procurement

Automate sourcing decisions using real-time cost and supplier data.

With AI at its core, CorporateServe’s ERP for Manufacturing helps manufacturers achieve higher productivity, precision and profitability.

Key Benefits

- End-to-end visibility from planning to production.

- Streamlined operations and improved delivery accuracy.

- Reduced operational costs through optimized resource use.

- Real-time insights for faster, data-driven decisions.

- Enhanced traceability and quality control.

- Seamless collaboration between engineering, production and procurement teams.

- Agile response to design changes and market fluctuations.

- Integrated compliance and audit-ready data management.

Integration That Keeps Production in Sync

CorporateServe’s ERP integrates seamlessly across systems and workflows to ensure complete operational alignment.

How ERP Supports Industry Standards?

Our ERP solution aligns with international standards and manufacturing best practices:

ISO 9001 & ISO 14001

Quality and environmental compliance

IATF 16949

Automotive and discrete manufacturing standard.

Lean & Six Sigma methodologies for process optimisation

Occupational Health & Safety (OHSAS) integration.

Traceability and audit trails for complete compliance visibility.

Why Choose Us?

Our Strengths:

A legacy of successful ERP implementations across sectors, backed by unmatched technical depth and delivery excellence.

Authorised partners of SAP, Microsoft and Epicor, giving clients access to world-class platforms and continuous innovation.

From consulting and implementation to managed services and optimisation, we take full ownership of your digital journey.

Every solution we build is driven by our clients’ goals, ensuring measurable business value and sustained success.

We integrate AI, analytics and automation into every solution, turning technology into a competitive advantage for the modern enterprise.